Challenge

Our esteemed partner, a renowned leader in the consumer electronics industry,

boasts an impressive product line of power amplifiers, loudspeakers, signal

processing, digital signal transport, and computer control systems. These

top-of-the-line offerings cater to the diverse needs of professional installed,

portable, production, corporate, and cinema customers worldwide.

With numerous separate units dedicated to manufacturing and testing, the daily

output of thousands of quality products is nothing short of exceptional. These

products are expertly crafted at multiple manufacturing units before undergoing

rigorous testing in various testing units.

However, this virtuoso enterprise faced a challenge when it came to

consolidating data from disparate systems across different geographies,

resulting in isolated silos. To overcome this, the company recognized the need

for a unified view of Product Testing KPIs from all testing units.

At our side, we are proud to collaborate with this visionary client to achieve

this goal and empower their continued success in delivering unparalleled

quality and unparalleled products to a global audience.

Solution

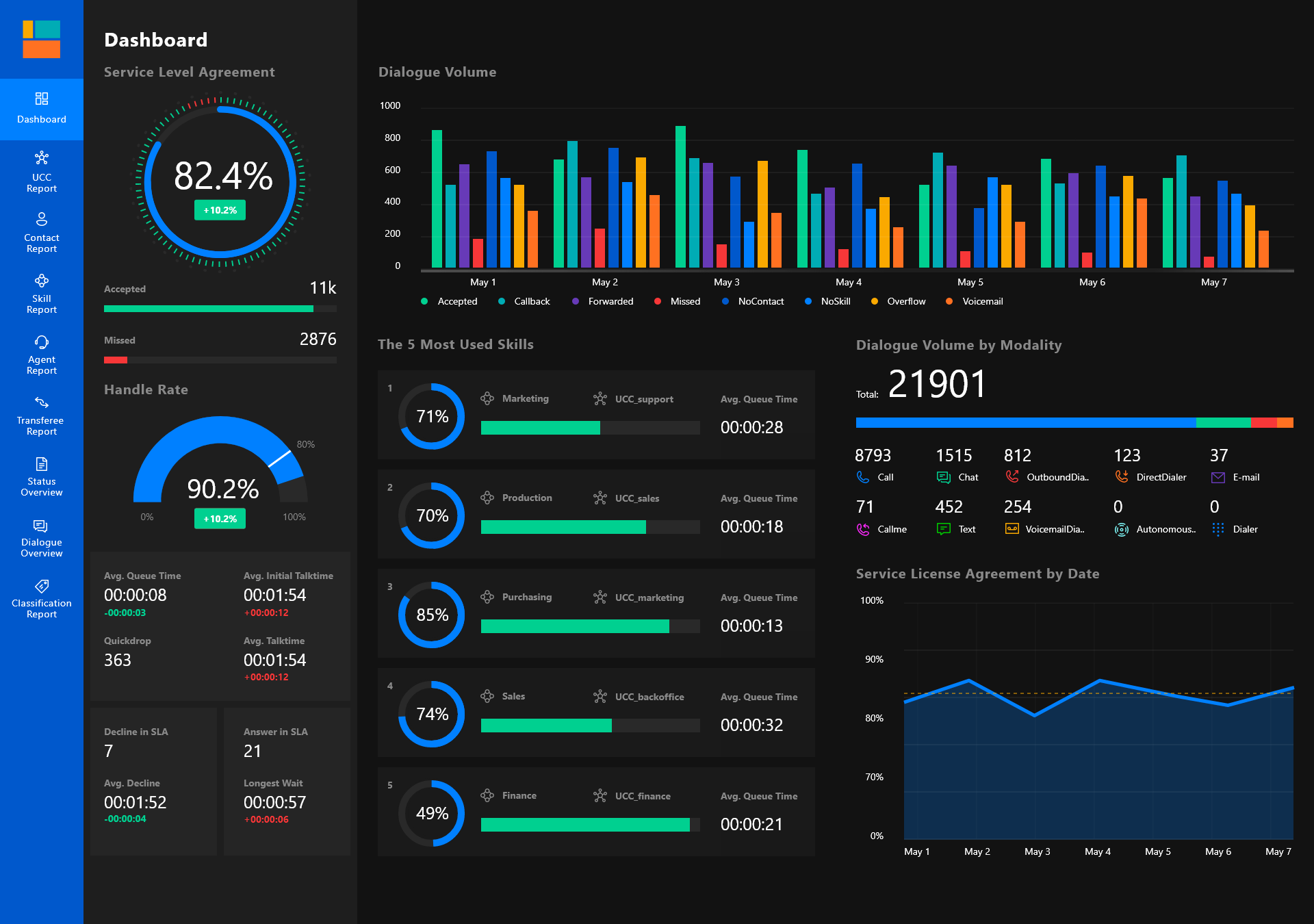

In order to leverage the strong visualization capabilities

of Power BI, Beyond Intranet recommended the creation of dashboards instead of

the usual SSRS reports. The Manufacturing Test Flow dashboard aimed to provide

our clients with invaluable insights and recommendations on how to improve

their production and test cycle. By analyzing and exploring opportunities to

enhance overall production, resource, and process efficiency, manufacturers

were able to identify areas for improvement.

The highly customizable dashboards proved to be a useful tool in monitoring key

performance indicators, such as the number of testing rounds required for a

device to pass. With the average threshold for this parameter set at >90%,

it was imperative that devices were declared 'Okay' in the first go in over 90%

of testing cycles. Another critical KPI was the time machines took to test a

device, with different threshold values for every device based on its

complexity and role in the system.

Overall, the Manufacturing Test Flow dashboard on Power BI was a valuable

resource for manufacturers looking to optimize their production and testing

processes.

Results

The Manufacturing Test Flow dashboard proved to be an

invaluable tool for our client, yielding powerful insights from their device

manufacturing and testing data. With highly customizable dashboards and

exceptional visualization capabilities, users could quickly and accurately

pinpoint the root cause of any issues, whether in manufacturing or testing. By

identifying which manufacturing or testing unit was producing defective

components/devices, users could adopt corrective measures and significantly

improve product quality.

Moreover, the dashboard enabled our client to determine whether challenges in

testing methodology or human error were responsible for any shortcomings. This

helped them refine their existing training methodology and optimize their

resources for enhanced efficiency.

With the ability to drill down and access granular reports on the entire

production and test process, our client's key stakeholders could make informed

decisions, leading to faster go-to-market and greater product accuracy. In

short, the Manufacturing Test Flow dashboard was a game-changer for our client

in the highly competitive manufacturing industry.